The basic principle of optical non-thermalization technology is to use the temperature characteristics of different optical materials, such as linear expansion coefficient, refractive index temperature gradient, etc. to select materials appropriately and distribute the focal lengths of each lens reasonably, so that the defocus amount generated by the entire optical system itself is consistent with the thermal expansion of the barrel while meeting the imaging quality requirements of the system. Optical non-thermalization design belongs to passive temperature compensation.

For optical systems that require both chromatic and thermal correction, the following three conditions must be met: focal length, color correction, and thermal correction. Infrared optical systems require at least three focal lengths to achieve simultaneous correction of thermal and chromatic aberration.

Note:

The statement that infrared optics systems require at least three focal lengths does not mean that the optical system needs at least three lenses. For example, a diffractive surface can be used in the system to provide focal length and reduce the number of lenses.

In the process of non-thermalization design of infrared optical systems, the following issues should be noted:

With the change of temperature, the original aberration compensation relationship may be destroyed, and the best focusing position of the system may change nonlinearly with temperature.

For reflective systems, if the material used to make the mirror is the same as that of the barrel (or the thermal expansion coefficient of the material is the same), when the temperature changes, the system will only be magnified or shrunk to a certain extent, and the influence of temperature on the system performance is not significant, and thermal correction design is not required in principle.

Because the mechanical barrel that holds the lens is complex in most cases, and the way the barrel expands (or contracts) with temperature may not be the same for different barrel structures. In non-thermalization design, based on the non-thermalization equation given earlier and according to the specific analysis of different barrel structures, the thermal correction effect should be ensured to achieve good performance.

In view of the above uncertainty factors, the optical system designed based on the IR optics non-thermalization technology should also have adjustment links to ensure practicality and safety.

If the infrared optics system allows for focus adjustment during use, it does not need non-thermalization design at all. Therefore, it is essential to understand the user's requirements before designing.

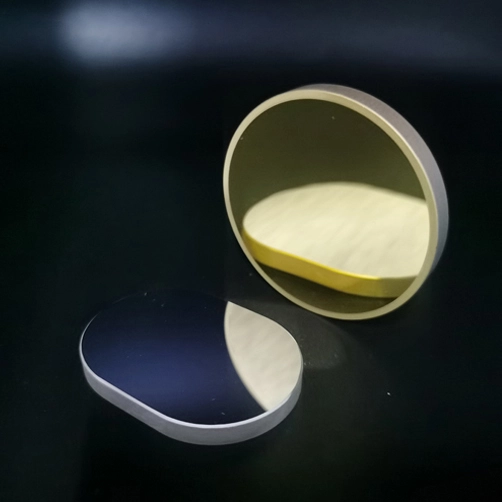

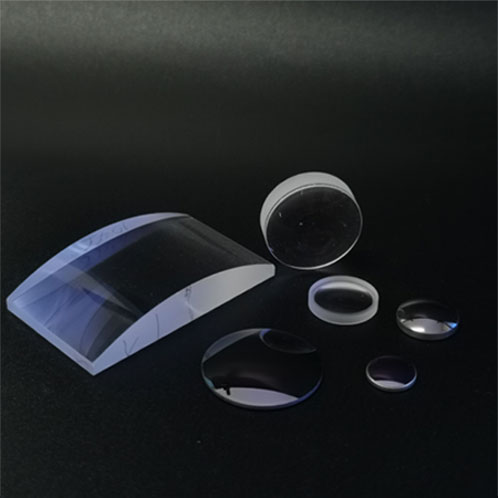

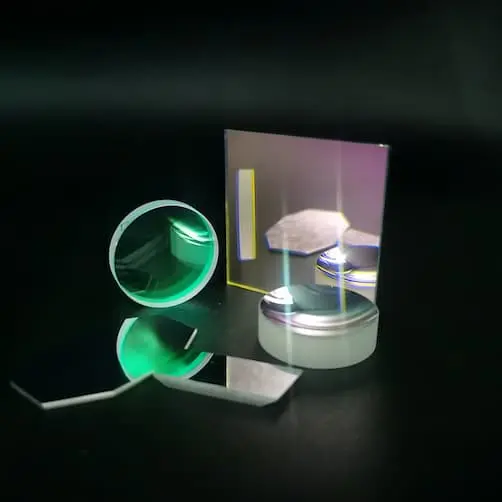

TC Optics is a manufacturer of optical components. We are committed to manufacturing windows, spherical lenses, aspheric lenses, prisms, filters, and mirrors. Welcome to consult us.