Typically, the three-dimensional form is that of a paraboloid, but there are also parabolic mirrors for sale which are curved in only one direction and therefore focus light only in that direction (similar to cylindrical lenses). Our company as one of parabolic mirror suppliers/ manufacturers provides large and small parabolic mirror of high quality.

Metallic Coating | Unprotected Gold |

Reflectance (Average) | >97% from 800 nm to 20 µm |

Off-Axis Angle | 90° |

Clear Aperture | >90% of Diameter |

Surface Roughness (RMS) | < 100 Å |

Surface Quality | 40-20 Scratch-Dig |

Parent Focal Length Tolerance | ±1% |

Reflected Focal Length Tolerance | ±1% |

Substrate | Aluminum |

Manufacturing Process | Diamond Turned |

Usually, people use the paraboloidal mirror when the beam needs to be strictly focused and collimated, or collimate the strictly focused beam, and the beam divergence is very strong at the focus. For example, this is necessary for high-order harmonic generation, laser material processing, waveguide free supercontinuum generation (requiring extreme optical intensity) and fluorescence microscopy. In this application, off-axis paraboloid mirror is often required.

In other cases, the beam divergence is small, but the mirror must be used away from the center. For example, the pump radiation in a thin disk laser is often redirected with a parabolic mirror and a prism reflector. In addition, paraboloidal mirrors are often used in telescopes, laser scanning systems, spectrometers and lighting.

However, in most cases, laser mirrors can be used to focus the laser beam, because the beam divergence involved is moderate.

Some parabolic mirror uses are provided in extreme spectral regions, for example, in the optical fields of infrared optics, ultraviolet optics and even x-ray lasers.

All kinds of applications need paraboloid mirrors as customized optical devices. Because paraboloid mirrors have more basic equipment parameters than ordinary spherical mirrors, it is difficult to obtain satisfactory mirrors in all aspects from stock. In addition to the characteristics of the reflecting surface, the geometry of the substrate is also important.

Parabolic mirrors play a crucial role in satellite communication and radar systems as they are used to transmit and receive signals. Here are their roles explained in detail:

1. Satellite Communication: Parabolic mirrors are used in satellite communication systems to transmit and receive electromagnetic signals, such as radio, television, internet, and telephone signals. They are typically placed at the focal point of a parabolic reflector antenna. The parabolic shape allows the signals to be focused and concentrated, resulting in increased signal strength and range.

2. Radar Systems: Parabolic mirrors are fundamental components of radar systems as they are used to reflect and focus radar signals. In radar applications, the parabolic mirror is often mounted on a rotating platform, allowing it to scan the surrounding area. As the mirror rotates, it reflects the emitted radar signals and collects the returning signals. This focused reflection allows radar systems to accurately measure the distance, speed, and direction of objects within a given range.

In both satellite communication and radar systems, the size and curvature of the parabolic mirror are crucial for achieving accurate signal transmission and reception. The reflector surface needs to be carefully designed and aligned to optimize the signal strength and achieve optimal performance in these critical applications.

Reflecting telescope usually uses a parabolic mirror provided by optical mirrors supplier because a parabola will focus all on axis light rays at the same point. The result is a higher quality image than the more easily made spherical mirror. An easier to make spherical mirror will focus light rays arriving at different distances from the central axis at slightly different focal lengths, resulting in a blurred image.

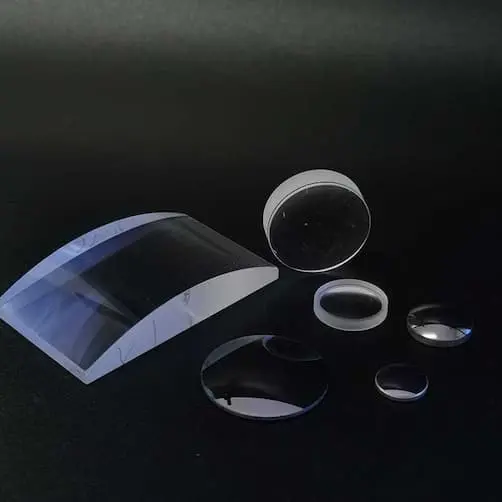

A parabolic mirror is a concave reflector used to project or collect energy or a type of radiation, including light, sound or radio waves. Its shape is like a plate, which is composed of paraboloids and is round. The shape of the surface is produced by a parabola rotating around its axis.

The easiest way is to cut and fold a flat sheet into a parabolic dish. Then glue a layer of aluminum foil on its inner surface, for reflectivity. The flat sheet can be as cheap as cardboard. However water resistant material, such as plastic or metal, will last longer from the custom lens manufacturers.

Parabolic mirrors have the ability to concentrate all the energy reflected at them into one focal point or to reflect parallel beams from an energy source placed at their focal point. So we use concentrate all the energy reflected at focal point.

If you would like to build your own precision optical products or request a quote, please click one of the two buttons below. Otherwise, please fill out the form below with any questions or concerns.

Address

No. 1567 Liu Ying Lu, Kuan Cheng District, Chang Chun, P.R. China

Call Us

86-431-89851801