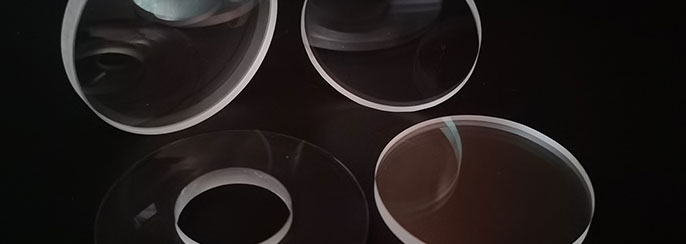

As one of leading optical manufacturing companies, our optical windows provide excellent transmission characteristics, with a high degree of clarity and low levels of distortion, and can be coated or treated to enhance their performance and durability. They are built to withstand even the most demanding environmental conditions, including high temperatures, pressure, or chemical exposure, ensuring long-term reliability and consistent performance.

The selection of optical window materials can be a complex process as it depends on the application requirements, environmental factors, and optical properties of the material. Here are some key factors to consider when selecting optical window materials:

1. Transmission: The material should have high transmission in the wavelength range of interest, allowing as much light as possible to pass through the window.

2. Refractive Index: The refractive index of the material should be close to that of the surrounding medium or the optical system, to minimize reflections and optimize light transmission.

3. Thermal properties: The material should have good thermal stability and resistance to thermal cycling, as well as low thermal expansion coefficient to minimize thermal stress.

4. Mechanical Properties: The material should have appropriate mechanical properties, such as strength, rigidity, and durability, to withstand the environmental factors and ensure long-term reliability of the optical system.

5. Chemical compatibility: The material should be compatible with the chemicals used in the system, as well as the surrounding environment, to avoid degradation or contamination.

6. Cost: The material choice should be practical within the budget.

Some common materials used for optical windows include:

Glass: Used for visible light range applications, usually low cost.

Quartz: Used for UV and visible applications, high transmission, and temperature-resistant. (quartz glass window)

Sapphire: Hard and temperature-resistant, commonly used for high-pressure conditions. (custom sapphire glass)

Silicon: Good in the IR range, durable material.

Magnesium fluoride: Used specifically for UV applications, with high transmission.

The material with the appropriate combination of properties should be chosen based on the specific requirements of the application.

TC optics, one of reputable and professional chinese optics manufacturers, are good at producing Laser optical windows glass with flatness L/20 And scratch dig 10-5. We can achieve a high damage threshold. We can make hexagonal windows and differently shaped windows. Our customers are very satisfied with our window quality and we have high volume production capability. if you have this kind of request, please contact us.

We take pride in our ability to deliver high-quality optical windows at competitive prices, with fast turnaround times and unmatched customer service. Whether you need a single custom window or a large production run, our team of experienced engineers and technicians are here to help you every step of the way.

Our extensive selection of optical windows includes UV windows, visible windows, IR windows, and more, all made to the highest quality standards using the latest manufacturing techniques and equipment. Contact us today to learn more about our products and services, and how we can help you achieve your optical window needs.

The larger the quantity of pieces that can be used in an application, the less expensive each part becomes as material, labor, and coating charges can be divided over the total number of parts.

Specified in inches or mm and typically given a +/- value.

Commercial grade mirrors are generally made from less expensive materials such as soda-lime glass or borofloat.

Commercial grade mirrors, suitable for non-critical applications, easily manufactured, lowest cost.

An optical window is a transparent material that allows the passage of electromagnetic radiation in a particular range of wavelengths. It is used as a protective barrier that protects optical components, sensors, or detectors from environmental factors such as temperature, moisture, and dirt. At the same time, it also allows the transmission of light or other electromagnetic waves through the window.

The properties of an optical window vary depending on the material used to make it. Some common materials used for optical windows include glass, sapphire, quartz, and plastic. The shape of the optical window can also vary depending on the application, and may include round, square, rectangular or custom shapes. The optical window plays an important role in many optical systems, as it can significantly impact the performance of the system by affecting factors such as light transmission, reflection, and refraction.

Ultraviolet (UV) windows are optical windows that are transparent to ultraviolet light, which refers to the portion of the electromagnetic spectrum with wavelengths shorter than visible light. UV windows typically allow UV radiation with wavelengths between 180-400 nanometers (nm) to pass through while blocking other wavelengths.

UV windows are used in many applications that require UV radiation to be transmitted, such as UV spectroscopy, analytical chemistry, and imaging. They are also used for UV disinfection, where UV light is used to kill bacteria and viruses.

UV windows are typically made from materials such as quartz, fused silica, sapphire, and magnesium fluoride, which are highly transparent to UV radiation. The windows can be of various shapes or sizes depending on the application requirements.

UV windows are often coated or treated to minimize reflection and extend their durability. Additionally, the use of UV windows can protect other components in the system from damage by UV radiation.

Visible Windows (VIS) are optical windows that are transparent to visible light (the portion of the electromagnetic spectrum between about 400 to 700 nanometers). They are commonly used in optical systems that utilize visible light, including cameras, optical sensors, and spectrometers.

Visible windows are typically made from materials such as glass or quartz, which are highly transparent to visible light and have good optical transmission characteristics. The shape of visible windows can vary depending on the optical system being used and the requirements of the application.

In addition to their use in optical systems, visible windows are also used in many displays, such as computer screens, televisions, and mobile devices. The transparency of the visible window allows the user to see the image produced by the display while also protecting the sensitive electronics within the display.

Infrared (IR) windows are specialized devices that are used to protect personnel from the dangers of arc flash events while still allowing infrared thermography inspection of electrical equipment. IR windows are transparent to infrared radiation and are installed on the metal enclosures of electrical panels, which allows thermographers to safely view, capture and analyze thermal data without having to open the panel or remove its cover.

IR windows are typically made from materials that are specially coated to minimize reflection and extend their durability. The most common materials used to make IR windows are polymers, composites, and crystals like quartz or sapphire. They can be circular, rectangle, or other custom shapes depending on the application.

The use of IR windows can help enhance the safety and reliability of electrical systems, as regular inspections can identify hotspots or potential equipment failures, allowing corrective action to be taken before a major problem or arc flash event occurs.

The shape of the optical window required depends on the specific application and the optical system being used. The most common shapes for optical windows are round, square, rectangular or custom shapes based on specific requirements. The shape of the optical window can affect factors such as the amount of light transmission, the angle of incidence, and the overall size and weight of the system. In some cases, a particular shape may be required for compatibility with the overall design of the optical system or for ease of alignment and positioning. Ultimately, the choice of shape will depend on the specific needs of the application and the optical system being used.

The optical window wavelength refers to the range of wavelengths of electromagnetic radiation that can pass through a specific material or medium without being absorbed or significantly scattered. The optical window varies depending on the material and can range from the ultraviolet (UV) to the near-infrared (NIR) spectrum. For example, for air, the optical window is typically considered to be between 300 nanometers (nm) to 1,200 nm, whereas for silica glass, it is approximately between 300 nm to 2,500 nm.

If you would like to build your own precision optical products or request a quote, please click one of the two buttons below. Otherwise, please fill out the form below with any questions or concerns.

Address

No. 1567 Liu Ying Lu, Kuan Cheng District, Chang Chun, P.R. China

Call Us

86-431-89851801