Silicon has a low 2.329 g/cm3 density which is half the density of Germanium, making it ideal for weight-sensitive applications, such as silicon windows. Silicon's price is much better compared with Germanium. Many military brand companies choose TC Optics Silicon lenses or windows.

Material | Silicon/silica |

Diameter | 1 to 500 mm |

Diameter Tolerance | +0/-0.02 mm |

Thickness Tolerance | ±0.01 mm |

Surface Quality | 10-5 |

Surface Figure | λ/10 |

Parallelism | 1 Minute |

Coating | Uncoated, AR, HR, Beamsplitter, etc. |

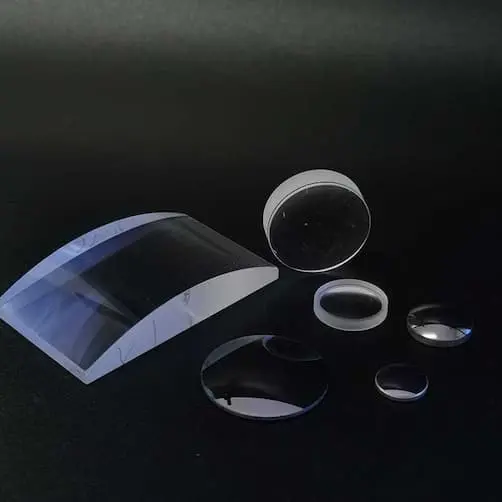

Types of optical window glass for your needs:

Fused silica window

Silicon window

Silicon windows have a high refractive index of about 3.4 and a low absorption coefficient in the mid-IR range, making them an ideal material for use in IR spectroscopy and imaging applications. They have a broad transmission range from 1-8 μm and are particularly useful in the 1-5 μm range.

Silicon windows have high transmittance in the visible and near-infrared regions. Their transmission rate ranges from 50% to 95%, depending on the thickness of the silicon material and the specific wavelength being transmitted. They have high transmittance in the range of 1-7 µm, which is the near-infrared region, and some silicon windows can transmit light up to 14 µm, making them suitable for use in some mid-infrared applications as well. Silicon windows are often used in spectroscopy, microscopy, and other instrumentation applications where high transmission in the visible and near-infrared range is required. They are also highly resistant to temperature changes and mechanical stress, making them suitable for use in harsh environments.

Silicon windows are a relatively hard material with a Knoop hardness of about 1150. They have a density of 2.33 g/cm3 and a thermal conductivity of about 149 W/mK, making them highly thermally conductive and resistant to thermal shock.

Silicon (Si) windows are widely used in a variety of scientific and industrial applications due to their excellent optical properties, particularly in the infrared (IR) region. Silicon has a high refractive index and a low absorption coefficient in the mid-ir range, making it an ideal material for use in ir spectroscopy and imaging applications. Silicon windows are also used in high-power laser systems and as protective windows for thermal imaging cameras.

Si windows are commonly used in infrared spectroscopy and imaging applications due to their high transmittance in the mid-IR range. They are often used in Fourier transform infrared (FTIR) spectrometers, where they are used as beamsplitters or as windows for sample chambers.

Si windows are also used in high-power laser systems, where they are used as protective windows or lenses due to their high thermal conductivity and low absorption coefficient in the visible and near-IR range.

Si windows are used as protective windows in thermal imaging cameras, where they are used to protect the sensitive infrared detector from dust and other contaminants while allowing infrared radiation to pass through.

Handling and maintenance of silicon windows are important factors to ensure their longevity and optimal performance. Here are some guidelines for handling and maintaining silicon windows:

Handling:

- When handling silicon windows, it is important to use clean, lint-free gloves or tweezers to avoid contamination.

- Avoid touching the optical surface of the silicon window as it can leave fingerprints or oils that may affect its performance. If contact occurs, clean the surface thoroughly using appropriate cleaning techniques.

- Always handle silicon windows with care, avoiding dropping, bumping, or subjecting them to excessive force to prevent damage.

Cleaning:

- Prior to cleaning the silicon window, use compressed air or a soft brush to remove any loose particles or debris from the surface.

- Use a mild detergent or a specialized optical cleaning solution along with a lint-free cloth or lens tissue to clean the surface gently. Avoid using abrasive materials or harsh chemicals that can scratch or damage the window.

- If there are stubborn stains or contaminants, a solution of isopropyl alcohol or methanol can be used. Ensure that the Silicon window is compatible with these substances before use.

- After cleaning, inspect the window for any residue or streaks. If necessary, repeat the cleaning process until the surface is clean and free from any contaminants.

Storage:

- Store silicon windows in a clean, dry environment to prevent dust, moisture, or chemical exposure, which can deteriorate their performance.

- Place silicon windows in protective cases or wrap them in lint-free materials to avoid scratches or damage during storage.

- Avoid placing heavy objects on top of silicon windows to prevent any potential distortion or deformation.

By following these handling and maintenance guidelines, silicon windows can be kept in optimal condition, ensuring their longevity and effectiveness in various applications such as optical systems, sensors, or semiconductor devices.

What is the transmission range of Silica windows?

A: Silica windows have a broad transmission range from 1-8 μm and are particularly useful in the 1-5 μm range.

Can Silica windows be used in high-power laser systems?

A: Yes, Silica windows have a low absorption coefficient in the visible and near-IR range, making them an ideal choice for use in high-power laser systems.

What is the refractive index of Silicon?

A: The refractive index of Silicon is about 3.4.

What is the thermal conductivity of Silicon?

A: The thermal conductivity of Silicon is about 149 W/mK.

What is the typical thickness of Silica windows?

A: Silica windows are available in thicknesses ranging from a few millimeters to several centimeters, depending on the application.

If you would like to build your own precision optical products or request a quote, please click one of the two buttons below. Otherwise, please fill out the form below with any questions or concerns.

Address

No. 946,Chaoyue street,High-tech zone,Changchun city,Jilin

Call Us

+86-431-84563660