Anti-reflection coating is a special optical coating that effectively reduces light reflection, thus improving the efficiency of optical products. It is made of a non-metallic material, typically glass or quartz, and has a layered structure with a top layer of quartz, a bottom layer of metal, and a middle layer of a special coating that can block refracted light.

Anti-reflection coatings usually have a high reflectance to achieve the best optical performance. They can effectively reduce reflection, improve contrast, and thus enhance resolution and efficiency of light. Additionally, they can improve the visibility of reflected light, making optical products more attractive.

The function of anti-reflection coating is to prevent or reduce reflective phenomena. It can effectively reduce reflection, allowing light to enter and pass through objects more efficiently, thus improving the appearance and performance of the product. Anti-reflection coatings can effectively suppress reflective phenomena, improve image quality, enhance appearance, reduce background noise, reduce exposure time of optical systems, improve efficiency of optical systems, enhance the performance of optical products, and lower the impact of reflective phenomena on optical systems.

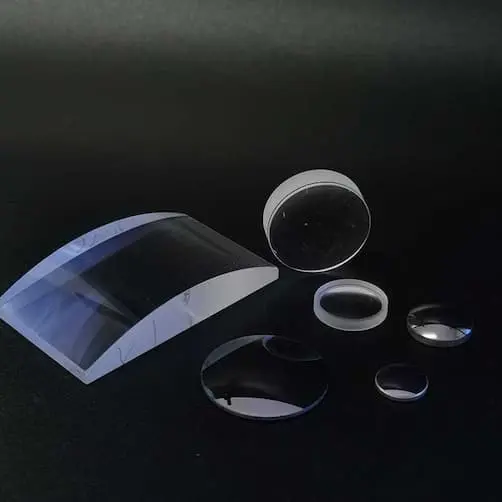

Anti-reflection coatings have many applications, including in car windows, phone screens, goggles, cameras, telescopes, displays, digital cameras, sunglasses, and more. They can prevent visual loss caused by reflective phenomena and protect the eyes from harm. They can also improve the performance of optical systems, reduce energy consumption of optical products, and thus improve people's quality of life.

The manufacturing process for anti-reflection coatings is also very complex and requires skilled technicians. They can be made using a variety of methods, such as sputtering, chemical deposition, magnetron sputtering, and co-focusing vapor deposition. Among these, sputtering is the most commonly used method, allowing for effective control of reflectance and thickness of the coating for optimal optical performance.

Overall, anti reflection coating is a highly technical product with wide applications, complex manufacturing processes, strong technical expertise, high reflectance, performance-enhancing capabilities, improved visibility, and improved quality of life. It is the best choice for manufacturing optical products today.